PFS Fueltec have partnered with VEGA to bring you a range of cutting-edge solutions that redefine the way you monitor and control fuel in industrial and commercial settings.

At the heart of our offerings lies VEGA's unwavering commitment to reliability and precision. With VEGA's controllers, level sensors, and remote displays, you gain access to a world of benefits that can transform your fuel management experience.

PFS Fueltec have partnered with VEGA to bring you a range of cutting-edge solutions that redefine the way you monitor and control fuel in industrial and commercial settings.

At the heart of our offerings lies VEGA's unwavering commitment to reliability and precision. With VEGA's

controllers, level sensors, and remote displays, you gain access to a world of benefits that can transform your fuel management experience, be it Bulk tank monitoring, day-tank control or even fuel polisher control systems.

Benefits of VEGA Systems:

-

Reliability: Trust in unwavering accuracy and performance. VEGA's solutions are engineered to deliver consistent and precise measurements, ensuring you have real-time data you can rely on.

-

Efficiency: Streamline your operations with bluetooth wireless setup and automated control options. VEGA systems simplify fuel monitoring, making life more efficient for installers and end-users.

-

Dependable supply: Say goodbye to the uncertainties of supply chain delays. We maintain a ready stock of common VEGA items, allowing you to access what you need promptly.

-

Swift Delivery: Even for items not in our stock, 5-day manufacturing lead time ensures you get essential equipment when you need it most.

Join us on a journey to elevate your fuel management experience. Explore our range of VEGA products below and discover how precision can make a world of difference in your operations. Trust PFS Fueltec to bring you the best in fuel management solutions.

VEGA's automated manufacturing processes ensure consistent quality and short lead-times.

Coupled with their continual innovation this ensures VEGA remains at the forefront of level measurement technology.

VEGA's solutions have a history of excelling in demanding environments, including fuel storage, chemical plants, food production, and more, providing peace of mind that you are working with the best of the best.

Innovating beyond traditional systems, PFS Fueltec presents the VEGASYS Gauge range.

Tailored for modern fuel storage installations, VEGASYS offers state-of-the-art tank monitoring and control at industrial and commercial fuel storage systems.

The VEGASYS series encapsulates a complete tank monitoring system in one comprehensive package, streamlining the process from selection to installation.

Designed as a drop-in alternative to the existing tank gauges available on the market, VEGASYS offers competitive pricing as well bulk-buy discounting for trade customers, this is the tank gauge you and your customers deserve.

Click the link to visit our VEGASYS product guide page.

- Compatibility: VEGAMET controllers utilise 4-20mAmp/HART inputs, ensuring easy integration with various sensors. (PS. We always recommend pairing the VEGAMET controllers with our VEGAPULS radar sensors for a fully integrated system)

- Multi-Functional: These controllers are versatile, serving multiple purposes at your fuel installation, including tank gauging, pump and valve control, and fuel polisher monitoring.

- Cost effective: With trade prices ranging from £485.00 for non-ATEX single sensor input versions with 3 relays, up to £888.00 for ATEX double sensor input versions with 6 relays, VEGAMET offers unmatchable value for money

- Easy-to-Read Displays: Enjoy configurable, easy-to-read backlit LCD displays that provide at-a-glance monitoring and status updates even in bright sunlight.

- Traffic Light Alarms: The entirety of the LCD display can be configured to change colour based on the readings from your connected sensors. This allows site operators to get instant notification of the status of their systems from a distance, in bright sunlight or at night. You can even set the screen to match the exact colour of your or your customers brand if you want to.

- Remote Display compatible: Use with VEGADIS remote displays to repeat level and volume information on a separate, low-cost, remote, back-lit display which needs no power source (it uses the 4-20mAmp current loop for power) - perfect for fill points or at-tank readouts.

- ATEX Intrinsically Safe Options: For ZONE 0 environments, VEGAMET controllers offer ATEX intrinsically safe sensor connections, ensuring safety and compliance. (Controllers to be installed outside of zoned areas)

- 2 inputs on one device: Save cost and monitor 2 sensors from a single device. Perfect for small tank farms or fuel polisher monitoring.

- Connectivity: With relays and 4-20 milliamp outputs built-in as standard, VEGAMET controllers easily connect to BMS, PLC and IOT systems, enhancing your process data integration capabilities

- Outdoor-Ready: VEGAMET controllers boast IP66/67 ratings, making them ideal for outdoor use, come rain or shine.

- Installer Friendly: All VEGAMET controllers from PFS come complete with all cable-glands and blanks required, as well as with quick-fit internal electrical connectors - saving time and frustration for wiring technicians

- Bluetooth Programming: Streamline programming through the integrated menu buttons, or via Bluetooth using the free VEGA TOOLS app on your smartphone or tablet, or the free VEGA PACTWARE app on your PC. Stay safe and dry whilst programming and commissioning.

- Quick Wizard Setup: Simplify your site setup by answering a handful of simple and easy to understand questions using the VEGA TOOLs app. Use the built-in tank calibration charts for typical tank shapes or use the integrated tank chart quick wizard to quickly create your own.

- Sensor Simulation: Simulate sensor readings in seconds, saving time and ensuring the flawless operation of your fuel management system during the User Acceptance Testing process. Simulating levels/volumes/percentages of levels or other process information will automatically cause Relays to switch based on your pre-programmed requirements - ensuring you can test valve open/close or pump/start stop in minutes.

- Automated Handover Paperwork: Once you've finished commissioning use the VEGA TOOLS app to output professional handover PDF's in seconds documenting setup parameters, measurement and status values

- Backup & Restore from the cloud: The VEGA TOOLS app allows you to backup system parameters to the VEGA CLOUD service free of charge. Use this to get systems back up and running quickly, or to copy and paste setups to similar devices to save time on site.

Monitor fuel storage tank levels and volumes for one to two tanks from a single controller using any brand or type of 4-20mAmp level sensor. (PS. We always recommend pairing the VEGAMET controllers with our VEGAPULS radar sensors for a fully integrated bulk-tank gauge system)

Output the measured level/volume to a 3rd party device (BMS, PLC, IOT controller) using the 4-20mAmp outputs.

Use the integrated relays to trigger external alarm devices based on current fuel levels (for overfill or run-dry alarms for instance).

Use the colour-changing screen capability to instantly show site staff the status of their tank fuel levels just by glancing at the screen, even from a distance

Monitor fuel storage tank levels and volumes of your day or belly tanks using any brand or type of 4-20mAmp level sensor. (PS. We always recommend pairing the VEGAMET controllers with our VEGA level sensors for a fully integrated system)

Output the measured level/volume to a 3rd party device (BMS, PLC, IOT controller) using the 4-20mAmp outputs.

Use the integrated relays to trigger pump-start and fill valve control or notify the status of tank conditions to your 3rd party devices

Simulate levels and test your entire day-tank fill control system using the VEGATOOLs app via the integrated Bluetooth connection.

Use the colour-changing screen capability to instantly show site staff the status of their tank fuel levels just by glancing at the screen.

Monitor fuel filter pressure and flow-rate status using a single controller.

Output the measurements to a 3rd party device (BMS, PLC, IOT controller) using the 4-20mAmp outputs.

Use the integrated relays to trigger external alarm devices based on current status (for filter-change needed or slow-flow issues).

Use the colour-changing screen capability to instantly show site staff the status of the polishing system just by glancing at the screen.

Explore VEGAMET: Watch Video Showcase!

VEGAMET

Unboxing video

Bluetooth Setup - Quick Wizard commissioning +

Relay programming

Bluetooth Setup - Simulation mode + Handover Documentation

Meet the VEGAMET product range:

VEGAMET 841

Controller for 1 x 4-20mA sensor inputs

(ATEX OPTIONAL)

- 1 x 4-20 mA sensor inputs

- 1 x 4-20 mA current outputs

- 3 x operating relay (1 of which can be used as a fail-safe relay).

VEGAMET 861

Controller for 1 x 4-20mA/HART sensor input (ATEX OPTIONAL)

- 1 x 4-20 mA/HART sensor input

- 1 x 4-20 mA current output

- 4 x operating relay (1 of which can be used as a fail-safe relay).

VEGAMET 842

Controller for 2 x 4-20mA sensor inputs

(ATEX OPTIONAL)

- 2 x 4-20 mA sensor inputs

- 2 x 4-20 mA current outputs

- 3 x operating relay (1 of which can be used as a fail-safe relay).

VEGAMET 862

Controller for 2 x 4-20mA/HART sensor inputs (ATEX OPTIONAL)

- 2 x 4-20 mA/HART sensor inputs

- 3 x 4-20 mA current outputs

- 6 x operating relay (1 of which can be used as a fail-safe relay).

Optional ATEX/UKEX approval for installation in an Ex-free area but with intrinsically safe sensor supply. Appropriate sensor can be installed Zone 0, 1, 2 (Class I Division 1, 2)

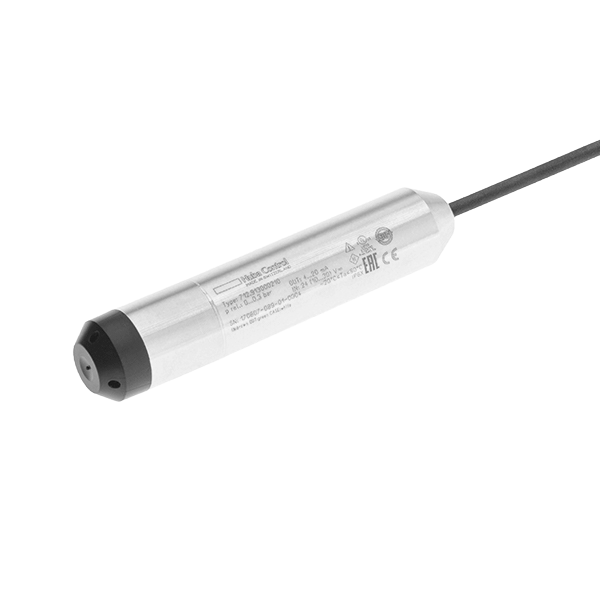

HUBA Pressure Level Sensors:

Elevate your fuel tank management with the HUBA ATEX Submersible Level Sensor, Type 712. Engineered for precision and reliability, this sensor stands as the paramount choice for applications demanding the utmost accuracy and longevity. With its origins in advanced pressure measurement technology, the Type 712 sensor integrates both relative and absolute pressure measuring cells. These cells are meticulously calibrated and feature an amplified signal output, ensuring precise level readings across diverse tank depths.

Product Offering:

- HSPLS-3M-10: 3 Meter Water Column version (with 10m cable). For Diesel tanks up to 3.5m. For Petrol Tanks up to 4m.

- HSPLS-5M-10: 5 Meter Water Column version (with 10m cable). For Diesel tanks up to 5.6m. For Petrol Tanks up to 6.7m.

- HSPLS-10M-20: 10 Meter Water Column version (with 20m cable). For Diesel tanks up to 11.3m. For Petrol Tanks up to 13.5m.

Key Features:

- Enhanced Compatibility: Designed to seamlessly integrate with 4-20mA gauge and control units, the Type 712 sensor facilitates easy incorporation into existing fuel tank gauging systems.

- Unmatched Accuracy: Boasting a resolution of 0.1% and a minimal deviation of +/- 0.8% at 25°C, this sensor delivers unparalleled precision in fuel level measurement.

- Robust Construction: Encased in durable stainless steel, the sensor is built to withstand harsh environments, ensuring long-term reliability and performance.

- Advanced Sensing Technology: The ceramic measuring cell at its core offers exceptional stability and sensitivity, catering to precise level sensing needs.

- Fuel and AdBlue Resistant Seals: Equipped with FPM Viton seals, the sensor is resistant to a wide range of fuels and AdBlue, enhancing its versatility across various applications.

- ATEX Certified: Ensuring the highest safety standards, the Type 712 sensor is ATEX certified to Ex II 1 G Ex ia IIC T4 Ga, making it suitable for use in Zone 0 hazardous environments.

- Extended Service Life: Designed with longevity in mind, the sensor ensures a reliable performance over an extended period, reducing the need for frequent replacements.

Applications:

Ideal for fuel tank gauging scenarios, the Type 712 sensor excels in environments where precision, durability, and safety are paramount. Its advanced features make it the sensor of choice for monitoring fuel levels in industrial tanks, ensuring efficient and safe operations.

Upgrade your fuel management system with the HUBA ATEX Submersible Level Sensor, Type 712, and experience a new standard in accuracy and reliability.

Electrical Overview:

- Output: 2 wire (4 ... 20 mA)

- Power Supply: 10 ... 30 VDC for 2 and 3 wire

- Load: < Power supply - 10 V [Ohm] for 2 wire

- Current Consumption: < 20 mA for 2 wire

Protection:

- Polarity reversal protection

- Short circuit proof

- Overvoltage protection: 36 VDC for 4 ... 20 mA / 0 ... 10 V

Dynamic Response:

- Response Time: < 2 ms

- Runtime: < 10 ms

- HSPLS-3M-10: 3 Meter Water Column version. For Diesel tanks up to 3.5m. For Petrol Tanks up to 4m.

(10m cable Length) - HSPLS-5M-10: 5 Meter Water Column version. For Diesel tanks up to 5.6m. For Petrol Tanks up to 6.7m.

(10m cable Length) - HSPLS-10M-20: 10 Meter Water Column version. For Diesel tanks up to 11.3m. For Petrol Tanks up to 13.5m.

(20m cable Length)

Medium Compatibility:

- Fuel oil, ultra-light (SN 181 160-2)

- Heavy fuel oil (SN 181 160-2)

- Diesel oil

- Benzine

- Drinking water (with EPDM O-ring)

Temperature:

- Medium and ambient: -20 ... +80 ºC

- Storage: -40 ... +80 ºC

Overload: 3x fs; max. 3 bar at 0.3 bar version

ACCURACY

- Max. Deviation at 25 ºC: ± 0.8% fs

- Resolution: 0.1% fs

- Long Term Stability: ± 0.25% fs acc. IEC EN 60770-1

- Thermal Characteristic: ± 0.2% fs/10K

Weight: Without Cable: ~ 200 g

Packaging: Single Packaging

Meet the HUBA product range:

HSPLS-3M-10

(HUBA ATEX Submersible

Level Sensor 0-3m

Water Column -10m cable)

HSPLS-5M-10

(HUBA ATEX Submersible

Level Sensor 0-5m

Water Column -10m cable)

HSPLS-10M-20

(HUBA ATEX Submersible

Level Sensor 0-10m

Water Column -20m cable)

VEGAPULS RADAR SENSORS:

In the realm of fuel monitoring, precision is paramount, and VEGAPULS Radar Sensors are the key to achieving unparalleled accuracy.

Designed to excel in diverse environments, these advanced sensors offer real-time, non-contact fuel level measurements, regardless of tank type or environmental conditions.

Whether you're overseeing fuel storage for industrial applications, commercial tank installations, or even complex critical power day-tank systems, VEGAPULS Radar Sensors provide the precision you can trust.

Say goodbye to outdated submerged pressure transducer sensors and welcome a new era of reliability and efficiency in fuel monitoring with VEGAPULS Radar Sensors.

- Incredible technology, low Cost: Our VEGA Radar sensors offer incredible value considering the technology and features they offer. Our entry level sensor with 0-8m range and +/-5mm accuracy is priced to trade customers at just £505.00, with the full featured ATEX rated 0-15m range sensors with +/-2mm accuracy priced at £818.00

- Versatile Applications: VEGAPULS Radar Sensors excel in diverse environments, delivering real-time, non-contact fuel level measurements, making them suitable for various tank types and environmental conditions.

- Wiring Options: Choose from pre-wired or wire-ready VEGAPULS Radar Sensors, providing flexibility in installation to simplify your setup.

- ATEX Approval: VEGAPULS Radar Sensors come with optional ATEX approval for Zone 0 environments, ensuring safety and compliance in hazardous settings.

-

Bluetooth Connectivity: Easily configure and monitor sensors via Bluetooth using the free VEGATOOLS app on your iOS or Android device or PC software, streamlining your setup and granting real-time data access at your fingertips.

-

Wide Depth Range: VEGAPULS Radar Sensors work with tanks ranging from 0.5 to 15m in depth, offering versatility for various tank sizes and applications.

-

Accuracy: Achieve precise fuel level measurements with VEGAPULS Radar Sensors, boasting an impressive +/- 2mm accuracy.

-

Non-Susceptibility to Density Changes: Unlike submerged pressure transducer sensors, VEGAPULS Radar Sensors are not susceptible to inaccuracies if the density of the fuel being monitored changes or is programmed incorrectly.

-

False Reading Suppression: These sensors can be programmed to ignore false readings caused by internal tank stays or cross-bars, ensuring accurate data without interference.

-

Simple Installation: VEGAPULS Radar Sensors feature straightforward screw-in installation, allowing for quick and hassle-free setup, saving you time and effort in the process.

Explore VEGAPLUS: Watch Video Showcase!

Unboxing video

Meet the VEGAPULS product range:

WIRE READY SENSORS (ready to accept field wiring)

VEGAPULS 11

Radar Sensor, 0-8m Range

Non-ATEX

(+/-5mm accuracy)

VEGAPULS 11 radar sensor for continuous level measurement. G1.5 Thread (1.5” BSPP)

Non-Atex Version for installation in Ex-free area.

VEGAPULS 11 is a basic sensor for non-contact level measurement in fuel and other liquid storage tanks.

Radar technology gives medium accuracy measurement independent of the density of the liquid being monitored.

The sensor has a low overall height, a +/-5mm accuracy and a 8m total measuring range; making it the a medium level accuracy measurement solution for all storage tanks, from belly tanks right up to 15m tall vertical bulk storage tanks.

Integrated Bluetooth technology means the sensor can be programmed, commissioned and troubleshooted quickly and easily via the free VEGATOOLS smartphone/tablet app, even when it is installed on a high tank top or in an area congested with industrial apparatus.

This sensor is designed for field wiring to be made directly into the sensor housing. An M20x1.5 Cable Gland is provided to seal incoming cable.

VEGAPULS 21

Radar Sensor, 0-15m Range

ATEX OPTIONAL

(+/-2mm accuracy)

VEGAPULS 21 radar sensor for continuous level measurement.

G1.5 Thread (1.5” BSPP)

Optional ATEX Approval, intrinsic safety, Zones 0,0/1,1,2

VEGAPULS 21 is the ideal sensor for non-contact level measurement in fuel and other liquid storage tanks.

Radar technology gives highly accurate level measurement independent of the density of the liquid being monitored.

The sensor has a low overall height, a +/-2mm accuracy and a 15m total measuring range; making it the perfect level measurement solution for all storage tanks, from belly tanks right up to 15m tall vertical bulk storage tanks.

Integrated Bluetooth technology means the sensor can be programmed, commissioned and troubleshooted quickly and easily via the free VEGATOOLS smartphone/tablet app, even when it is installed on a high tank top or in an area congested with industrial apparatus.

This sensor is designed for field wiring to be made directly into the sensor housing. An M20x1.5 Cable Gland is provided to seal incoming cable.

PRE-WIRED SENSORS

VEGAPULS C11

Radar Sensor, 0-8m Range

Non-ATEX

(+/-5mm accuracy)

VEGAPULS C 11 Wired radar sensor for continuous level measurement. G1.5 Thread (1.5” BSPP)

Non-Atex Version for installation in Ex-free area.

VEGAPULS C 11 is the ideal sensor for non-contact level measurement in fuel and other liquid storage tanks.

Radar technology gives highly accurate level measurement independent of the density of the liquid being monitored.

The sensor has a low overall height, a +/-5mm accuracy and a 8m total measuring range; making it the perfect level measurement solution for all storage tanks, from belly tanks right up to 8m tall vertical bulk storage tanks.

Integrated Bluetooth technology means the sensor can be programmed, commissioned and troubleshooted quickly and easily via the free VEGATOOLS smartphone/tablet app, even when it is installed on a high tank top or in an area congested with industrial apparatus.

VEGAPULS C21

Radar Sensor, 0-15m Range ATEX OPTIONAL

(+/-2mm accuracy)

VEGAPULS C 21 Wired radar sensor for continuous level measurement. G1.5 Thread (1.5” BSPP)

Optional ATEX/UKEX Approval, intrinsic safety, Zones 0,0/1,1,2

VEGAPULS C 21 is the ideal sensor for non-contact level measurement in fuel and other liquid storage tanks.

Radar technology gives highly accurate level measurement independent of the density of the liquid being monitored.

The sensor has a low overall height, a +/-2mm accuracy and a 15m total measuring range; making it the perfect level measurement solution for all storage tanks, from belly tanks right up to 15m tall vertical bulk storage tanks.

Integrated Bluetooth technology means the sensor can be programmed, commissioned and troubleshooted quickly and easily via the free VEGATOOLS smartphone/tablet app, even when it is installed on a high tank top or in an area congested with industrial apparatus.

VEGADIS REMOTE DISPLAYS:

In the realm of fuel monitoring, real-time information is essential, and VEGADIS Remote Displays put that vital data right at your fingertips.

These intuitive displays are designed to complement VEGA's precision sensors and controllers, providing instant access to crucial fuel level data from across your industrial or commercial installations.

Whether you need at-tank readouts or seek to equip fill points for delivery drivers with the information they need to safely and efficiently deliver fuel, VEGADIS Remote Displays empower you with real-time visibility and control.

What sets them apart is their seamless integration—they require no separate power source as they are powered by the 4-20mAmp loop from the VEGAMET controllers.

- Seamless Power Integration: VEGADIS Remote Displays are powered directly by the 4-20mAmp loop from VEGAMET controllers, eliminating the need for a separate power source.

- Flexible Installation Options: VEGADIS Remote Displays can be installed with flexibility. They can be placed in-line between the level sensor and the VEGAMET controller, providing real-time data for your fuel management system. Alternatively, they can be connected to the VEGAMET controller's 4-20mAmp output, allowing you to choose the configuration that best suits your setup.

- Effortless Readability: Equipped with a backlit LCD in dot matrix, these displays provide clear and easy-to-read fuel level information. Sensor readings can be displayed as scaled (eg. Litres), as a height (mm/cm), percentage or as a mixture of all 3. Other readings can be displayed where appropriate

- User-Friendly Interface: Adjustment elements with four keys allow for intuitive and straightforward configuration and adjustments.

-

Versatile Cable Entry: VEGADIS offers options for cable entry, including cable gland M20 x 1.5 for cables with a diameter of 5 to 9 mm, ensuring flexibility in installation.

-

Adaptable Wire Cross-Section: Compatible with a range of wire cross-sections, from massive wire to stranded wire with end sleeves, accommodating various wiring preferences.

-

Robust Housing: Housed in a durable plastic casing, VEGADIS Remote Displays boast a high protection rating of IP66/IP67 and NEMA Type 4X, making them suitable for challenging industrial environments.

- Wide Temperature Range: VEGADIS operates reliably in ambient temperatures spanning from -20°C to +70°C (-4°F to +158°F), ensuring functionality in diverse conditions.

- Compatibility with 3rd Party Equipment: These displays are not limited to VEGA's equipment alone. VEGADIS Remote Displays can also be seamlessly integrated with 3rd party 4-20mAmp gauges and sensors, offering versatility in monitoring and control, and ensuring they adapt to your specific needs.

Meet the VEGADIS product range:

VEGADIS 82

Remote display unit

4-20mA (ATEX OPTIONAL)

The VEGADIS 82 is a remote display unit for 4 … 20 mA sensors. The instrument can be looped in any position directly in the signal cable and is particularly useful where a volume/level indication is needed away from the main controller such as next to the fuel tank or at a filling point.

It operates as pure display instrument in a 4 … 20 mA current loop between a sensor and a controller, or via a controllers 4-20mA output.

Optional ATEX/UKEX II 1G, 2G Ex ia IIC T6 Ga, Gb

VEGADIS 82

Remote display unit

4-20mA/HART (ATEX OPTIONAL)

The VEGADIS 82 is a remote display unit for 4 … 20 mA sensors, optionally with HART protocol. The instrument can be looped in any position directly in the signal cable and is particularly useful where a volume/level indication is needed away from the main controller such as next to the fuel tank or at a filling point.

It operates as pure display instrument in a 4 … 20 mA/HART current loop between a sensor and a controller, or via a controllers 4-20mA output.

OPTIONAL ATEX/UKEX II 1G, 2G Ex ia IIC T6 Ga, Gb

Your Fuel Equipment One-Stop Shop!

We provide a range of fuel system storage and transfer equipment for all types of retail, commercial, critical power, marine, and railway fuel installations, including:

- Pipework

- Fuel Pumps & Pump Control Panels

- Fuel tank gauging

- Leak detection

- Polishing

- Signs and Labels

- Spill and Environmental products