Not all fuel polishers are created equally

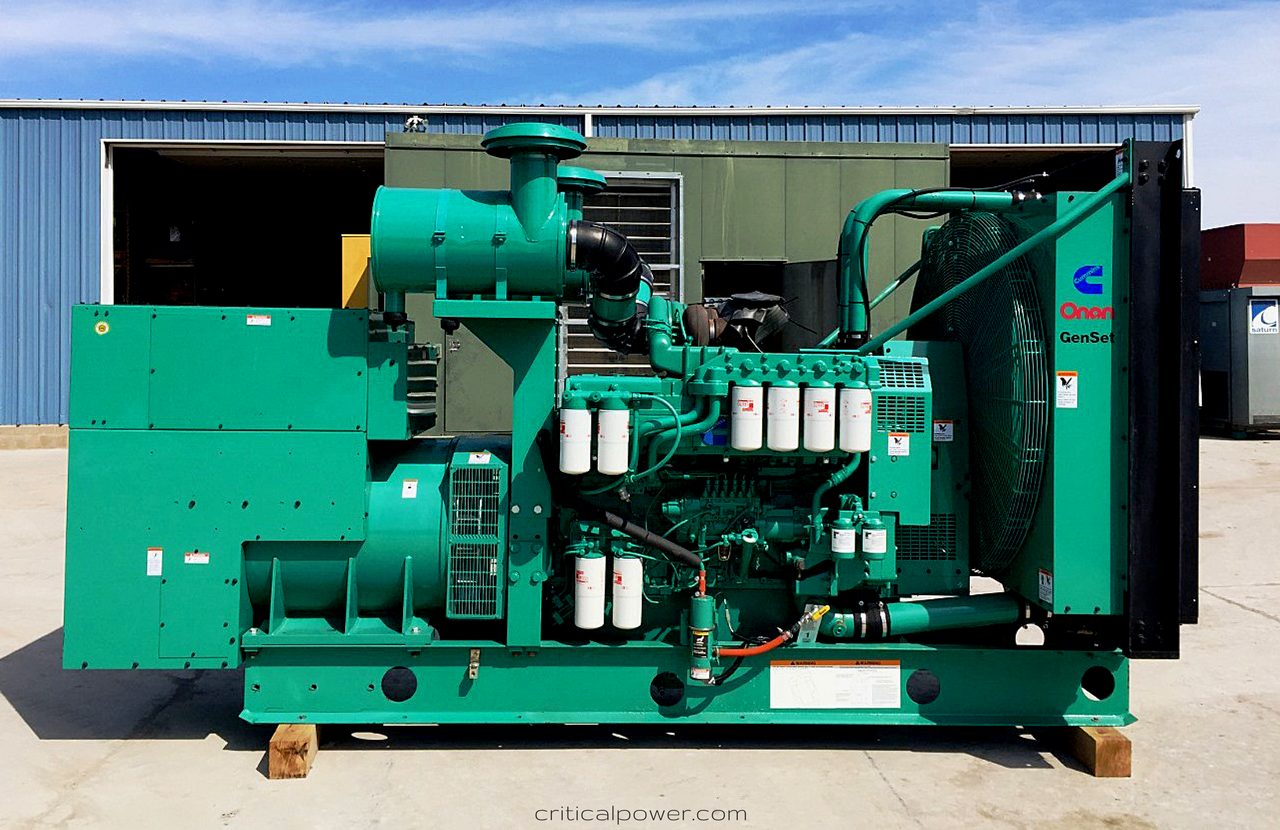

Specifying the correct fuel polisher for your Backup Generator diesel system is vitally important.

Get it wrong and your diesel generator could fail just when it is needed the most.

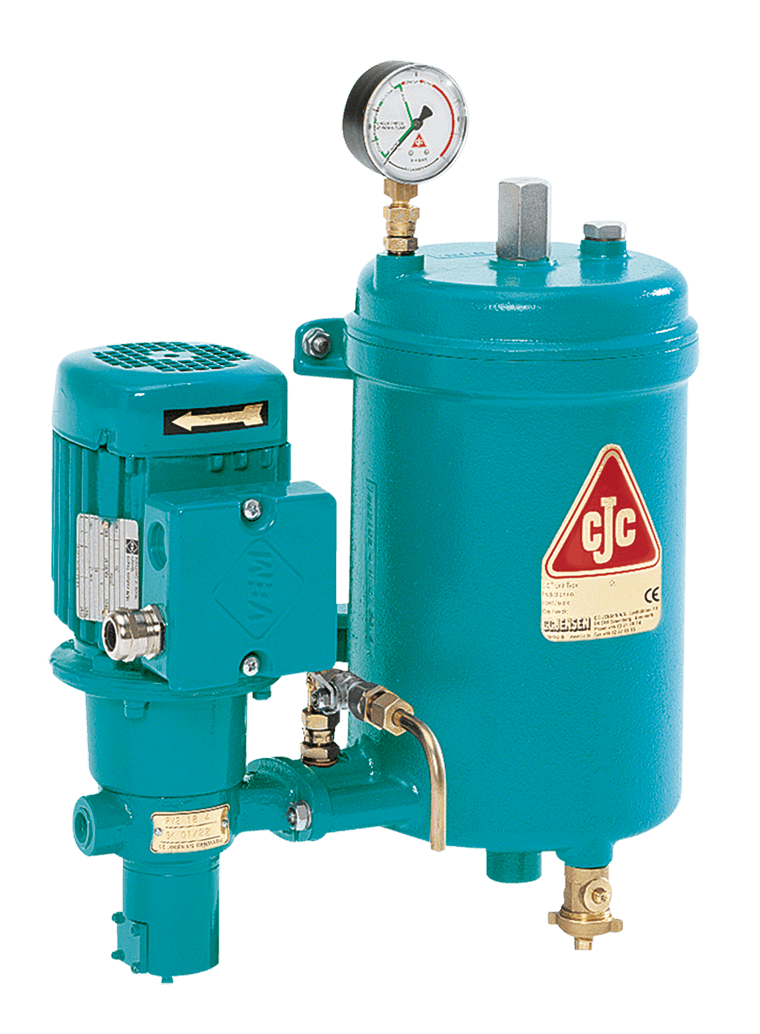

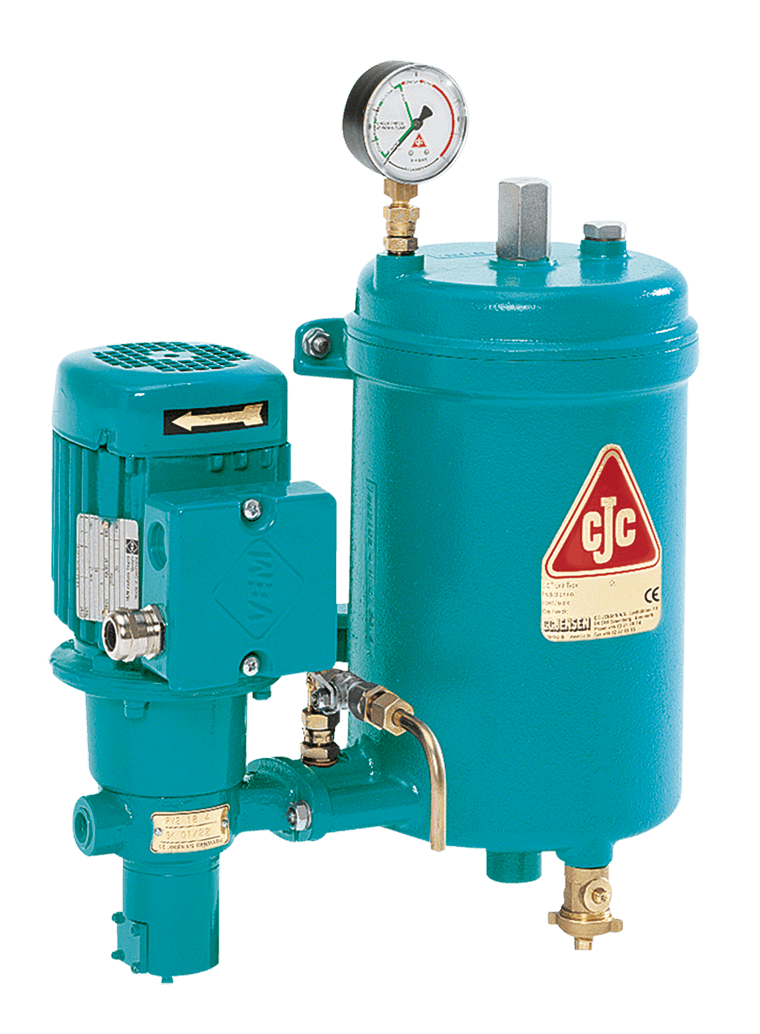

CC Jensen (CJC) have been leading the world in oil and diesel polishing/filtration systems for six decades.

The worlds shipping and wind-turbine industries already rely on CJC filters to clean diesel and oil in the most harsh and critical of environments. In fact 80% of the worlds wind turbines have CJC filters installed.

As the UK distributor of CJC polishing systems and other diesel equipment solutions for the backup generator market, we help our customers save cost and ensure uptime throughout everything we do.

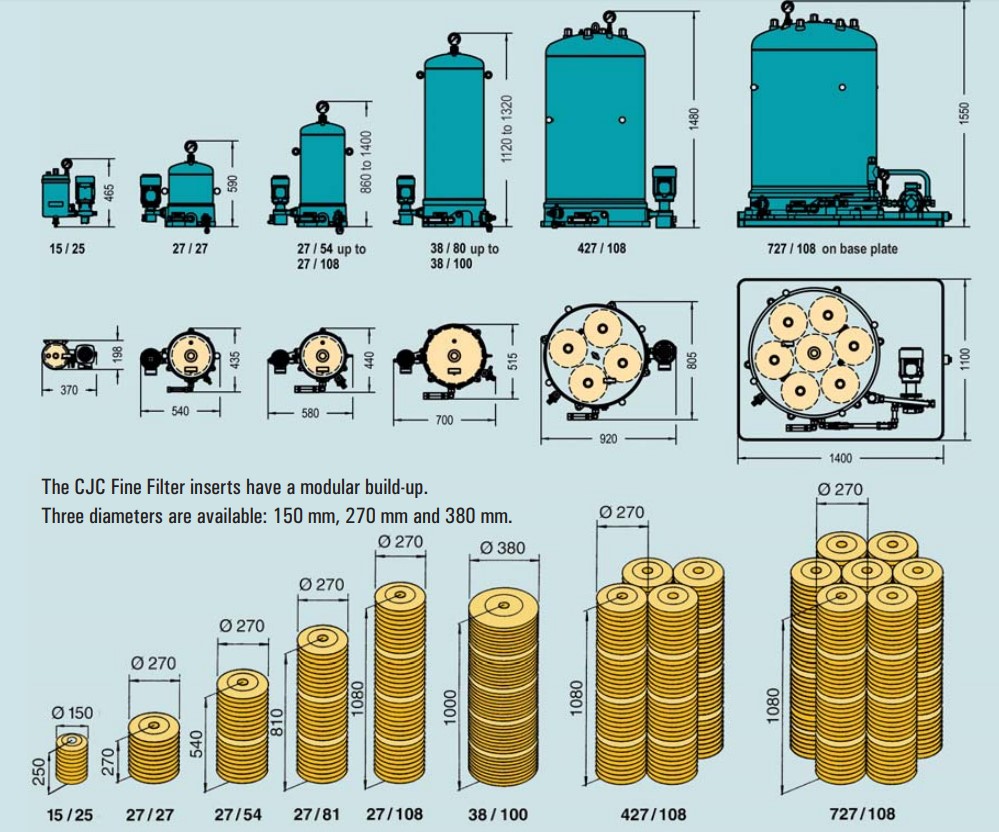

CJC Polishers - Buyers Guide

CJC Off line diesel polishers are easy to specify and easier to run.

Installed on bulk or belly tanks, they are designed to run 24/7, the integrated pump runs quietly with very low energy use.

They offer market leading particle filtration and water removal from a single filter with the industries largest dirt and water holding capacity.

| Diesel Tank Volume (ltrs) | 1,000 - 20,000 | 20,000 - 50,000 | 50,000 - 70,000 | 70,000-8000 | 80,000 - 100,000 |

| Recommended CJC Model # | HDU 15/25 | HDU 27/27 | HDU 27/54 | HDU 2781 | HDU 27/108 |

| Number of Filter inserts | 1 | 1 | 2 | 3 | 4 |

| Dirt Holding Capacity (ltrs) | 1.5 | 4 | 8 | 12 | 16 |

- Single or three phase pump motor options available

- Electrical junction box + start stop isolator included

- Mounted on leak stopping driptray

- Dial pressure gauge included to indicate filter when filters need replacing

- Mini-mess sampling point included

- Threaded BSP inlet and outlets

- Options

- BMS connectivity (pump on/off indicator, filter change alarm indicator, dry run indicator)

- Electronic particulate counter + humidity + temperature monitoring system

- Drip-tray leak detection

CONTACT US TODAY FOR PRICING AND INFO

Save Money

Cost-effective to purchase, CJC polishers extend the time between filter changes in your polisher by up to 10 x compared to other thin wall filter systems.

This can save thousands of pounds per year in filter costs on a typical diesel generator installation giving a ROI of a matter of months.

Ensure Up-time

CJC Filters will clean diesel to ISO 13/11/8 or even better which is much cleaner than OEM engine manufacturers require.

Water reduction to just 156 parts per million.

This will ensure your system starts when it is needed and can increase life expectancy of engine parts by a factor of 5.

Reduce Emissions

Burning cleaner diesel means engines run smoother, burn less fuel and their emissions are reduced dramatically.

CC Jensen fuel filter systems therefore can have a big effect on emissions and fuel efficiency at large generator installations.

Better for the planet and your customers bottom line.

Why diesel generator systems need fine filtration and water removal

In an attempt to reduce emissions and improve fuel efficiency, equipment manufacturers continuously develop new solutions for modern engines.

The High Pressure Common Rail (HPCR) fuel injection system is one of these landmarks which have now become standard in diesel generator engines.

Because a HPCR system operates under extremely high pressure with very small tolerances, it requires different fuel cleanliness standards. Under such circumstances the smallest particles have the biggest negative impact on the diesel fuel systems.

Diesel contamination

Water & Particles

Water and particles/dirt cause the main problems in diesel systems.

While both will have a direct negative impact on the engine; water found during storage will also lead to bacteria growth which will quickly clog fuel valves, injectors and in-line pressure filters causing engine stop.

Common problems caused by water and particles in the diesel are: rust/corrosion, cavitation, microbial contamination and abrasive wear.

There is a direct correlation between the water and particle level in diesel and the lifetime of critical components such as injectors, fuel pumps and filters.

Asphaltenes, Paraffins & Resin

As a by-product of the refining process and a natural consequence of fuel degradation processes modern diesel contain asphaltenes, paraffins and resin.

These are commonly known as organic debris, but in daily

language referred to as tar/asphalt, wax, sludge and diesel bugs.

Most of the organic debris are acidic and will cause corrosion of injectors, pumps and tanks. It will plug and damage your injectors affect combustion and eventually clog in-line filters. In short it will ruin your engine.

Reliability and Longevity of engines...

While most OEM engine manufacturers recommend a diesel cleanliness of ISO 18/16/13, the reality is that ISO 14/12/9 or even lower is needed to provide reliability of start/stop and to increase the expected component lifetime.

In a HPCR system operating under 2,000 - 3,000 bar pressure and needle valves with a clearance of 2-4 microns, the difference between ISO code 18/16/13 and 14/12/9

translates into several thousand extra operating hours on injectors and fuel pumps.

The high pressure through the injectors creates “blasting” with water droplets and particles; and it causes water implosions (cavitation) resulting in high wear rates on

injectors.

Furthermore, particles will generate wear on the entire injector system and lead to poor spray patterns. This results in incomplete combustions and reduced engine

component and oil lifetime. This is exacerbated by rust and corrosion.

CC Jensen - Optimum Filtration

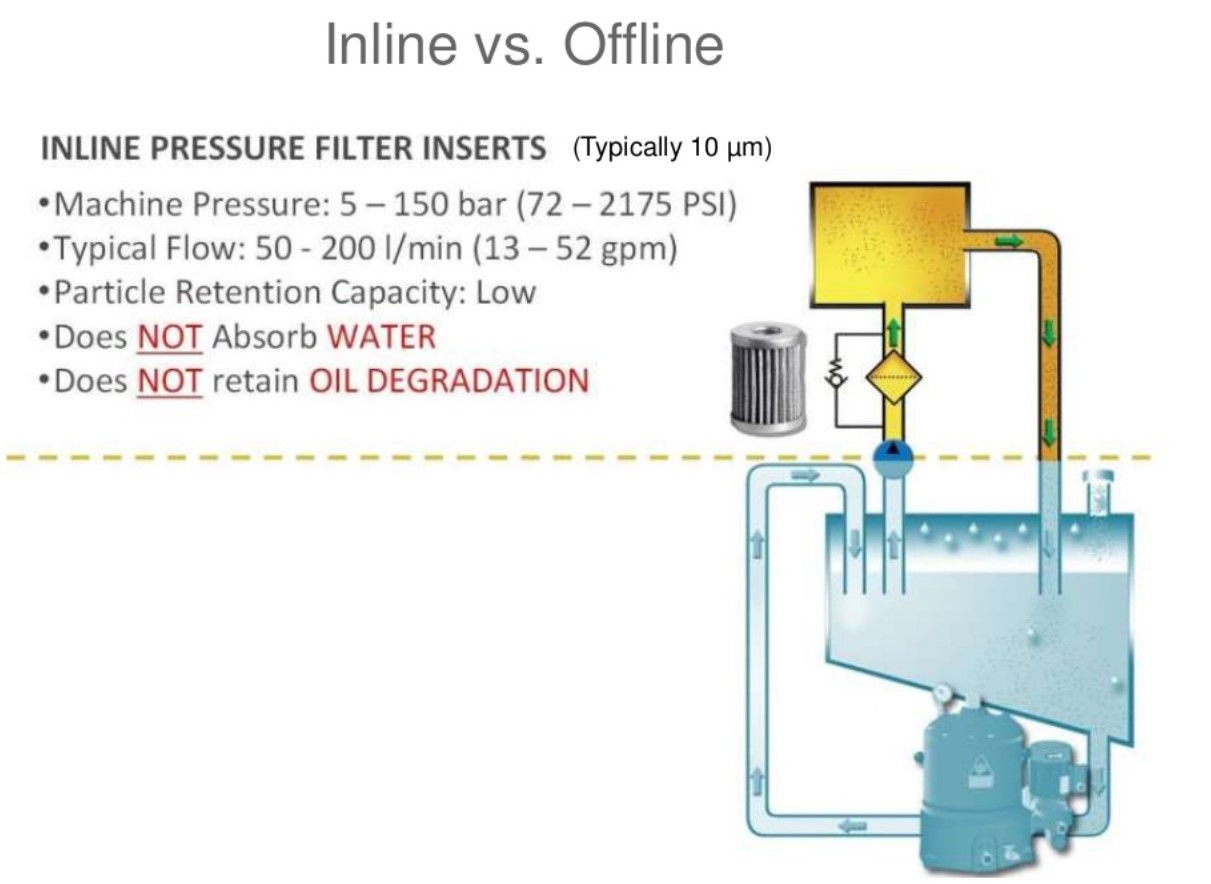

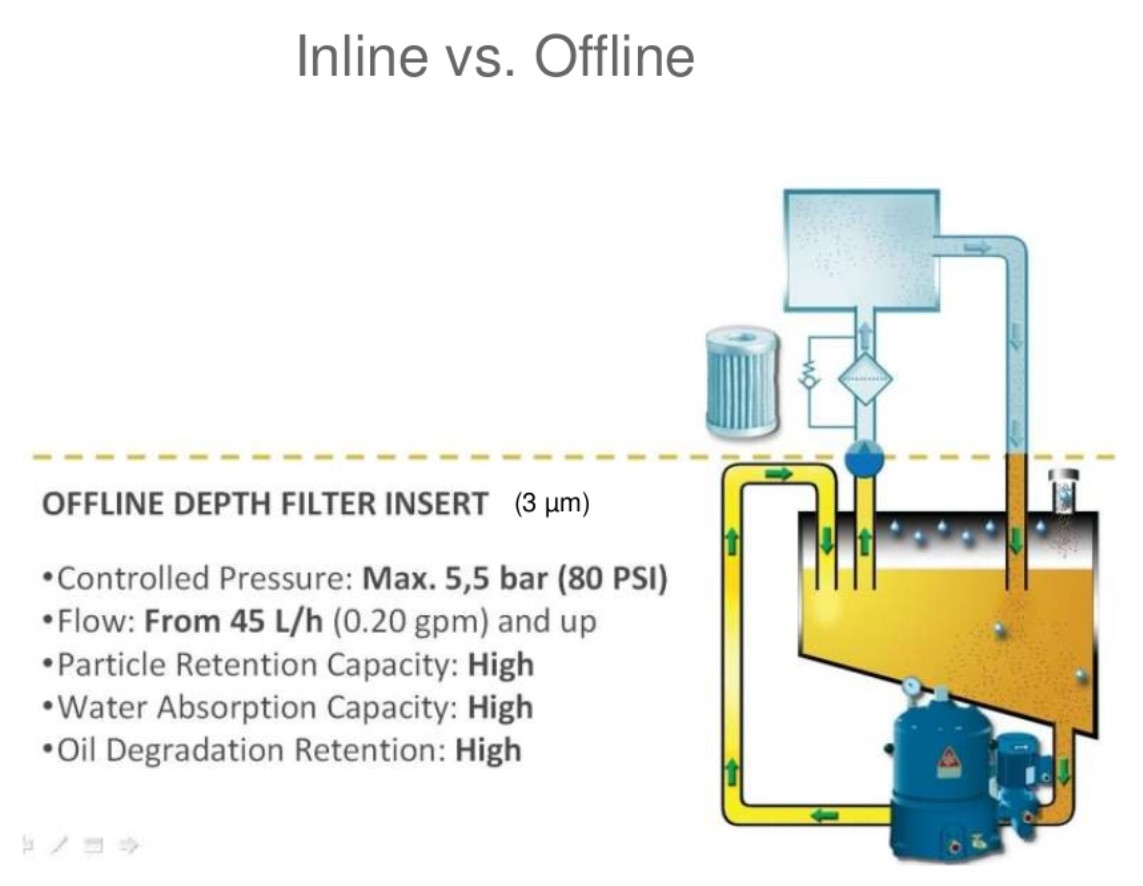

Compared to a normal in-line filter, a CJC™ Diesel Filter is significantly different.

The main differences are the dirt-holding capacity, the fine

filtration capabilities and the removal of particles, water and sludge - all through one single filter insert.

CJC™ Oil Filters have the highest dirt holding capacity in the market.

Each CJC™ Filter Insert provides a dirt holding capacity of up to 4kg and, as a CJC™ Filter Insert also absorbs water, each can retain up to 2kg of water.

Unlike thin-walled bag filters, the CJC™ Filter Insert is like a maze, where the oil passes through several layers of cellulose, called depth filtration.

The large particles are retained at the surface, and the smaller particles will enter the “maze” and are retained within the filter material.

CJC™ Filter Inserts have a 3 μm absolute rating. This means that 98.7% of particles 3 μm and larger

are removed in a single pass.

Furthermore, they also have a 0.8 μm nominal rating. This means that 50% of particles from 0.8 μm to 3 μm in size are

removed in a single pass.

Off-line vs In-line filters/polishers

Off line filter/polisher systems from CJC work independantly of the main fuel delivery system.

They can be installed on the bulk tanks, or on the day-tanks.

The integrated pump draws fuel in from the tank, through the filter, cleaning and de-watering, and then pumps the clean fuel back to the same tank, or back to a bulk tank.

We recommend that your off-line filter is sized to be able to filter the entire fuel capacity of your fuel tank twice per week.

Short term benefits of offline oil filtration:

- Reduced overall filtration costs (50-80%)

- No shutdown required for component changes

- Reduced equipment maintenance

- Minimal installation costs

- Minimal training required for operation

- No shutdown required for component changes

Long term benefits of offline oil filtration:

- Finer filtration removes more particles

- Extended component life

- Extended oil life

- Extended in-line filter life

- Reduced downtime due to equipment failure

- Reduced environmental impact